What makes The Kidney Project different?

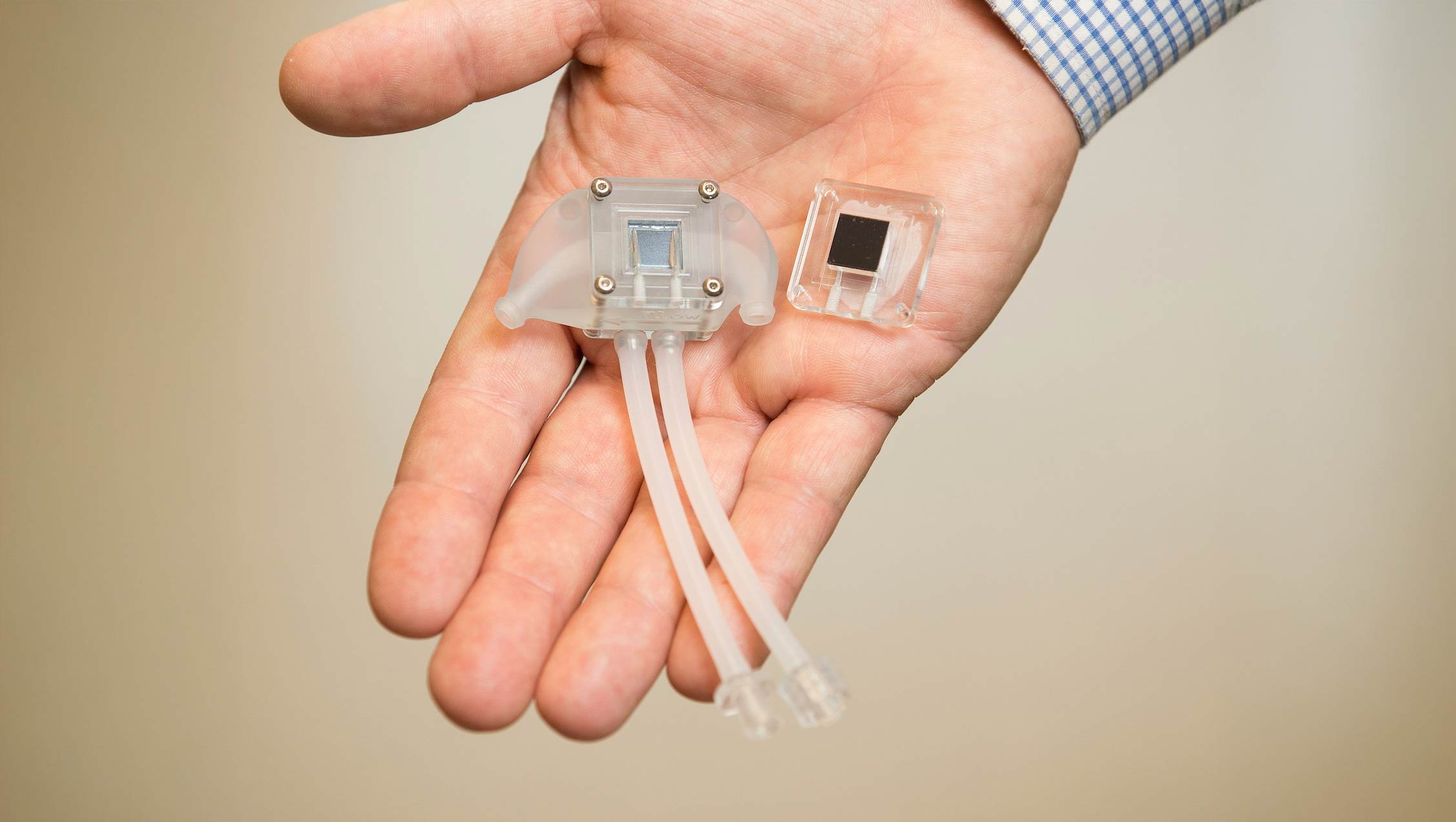

The basic technology of hemodialysis has been unchanged since the early 1970s. We are changing the underlying technology of the artificial filters that separate waste from blood. This allows us to miniaturize the filters so they can fit inside the human body.

We eliminate the electric pumps used in dialysis and allow the patient’s own heart to circulate blood to the filters. Instead of requiring hundreds of gallons of water for dialysis, we use the body’s own naturally evolved biological strategy to concentrate filtered waste into one or two liters of urine.

How does this artificial kidney work?

The implantable bioartificial kidney combines nano-technology with tissues from human kidney cells. The design features an artificial filtration unit to replace the cells damaged in end-stage renal failure, because functional filtration cells are not feasibly grown in culture.

Why do we use kidney cells in our biohybrid device?

Healthy kidneys filter 120 liters a day from blood but only produce 1-2 liters of urine each day. This is a small enough volume of fluid loss that can be balanced by normal eating and drinking. It takes energy to concentrate the body’s waste products and minimize fluid losses.

The cells in the kidney’s tubule grow easily in culture, and use chemical energy derived from the body’s nutrients to do the concentrating, so our implantable artificial kidney does not need to rely on electrical power and pumps. By using these technologies we can reduce the size and the power requirements of our implantable artificial kidney enough to allow implantation.

What inspired the design?

All filtration processes are a trade-off between selectivity and permeability. To use a familiar example, when straining boiled peas at the sink, one wishes to retain the peas for eating and quickly drain the hot water. The bigger the holes in the colander, the faster the water passes, but smaller peas might pass through the colander and be wasted.

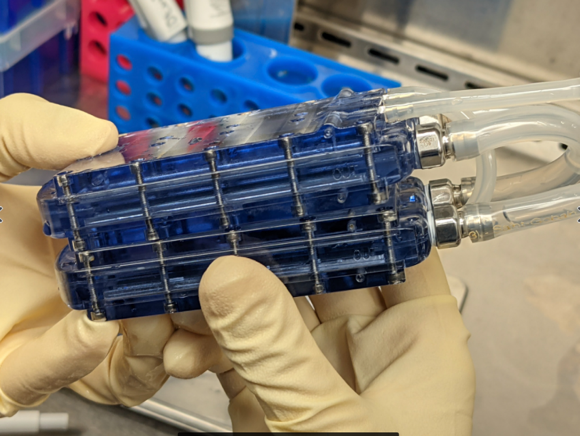

We examined the difference between round pores and slots and showed that slit pores optimize the permeability-selectivity tradeoff intrinsic to all filtration processes. We then chose silicon micro-machining technology to construct highly efficient slit-pore membranes, which allows precise control of the size and shape of each pore.

What about stem cells?

Cells grown in culture simply do not function the same as cells taken from human kidneys, a feature common to almost all stem cells. This phenomenon is known as “cell culture stress,” and it happens because cells cannot be continuously supplied with fresh nutrients and oxygen like they are in the body.

What does the bioreactor do?

The implantable artificial kidney uses human kidney cells from organs donated for transplantation, but which were later found to be unusable due to scarring. We culture regenerated cells from these failed transplants. The bioreactor then continuously suffuses the cultured cells with concentrations of nutrients and hormones that mimic the body’s natural state.

Learn more

Watch the video above to see Dr. William Fissell's Vanderbilt University Medical Center Department of Medicine Grand Rounds presentation, "Universal Donor Kidney: Bioengineering the end of scarcity."